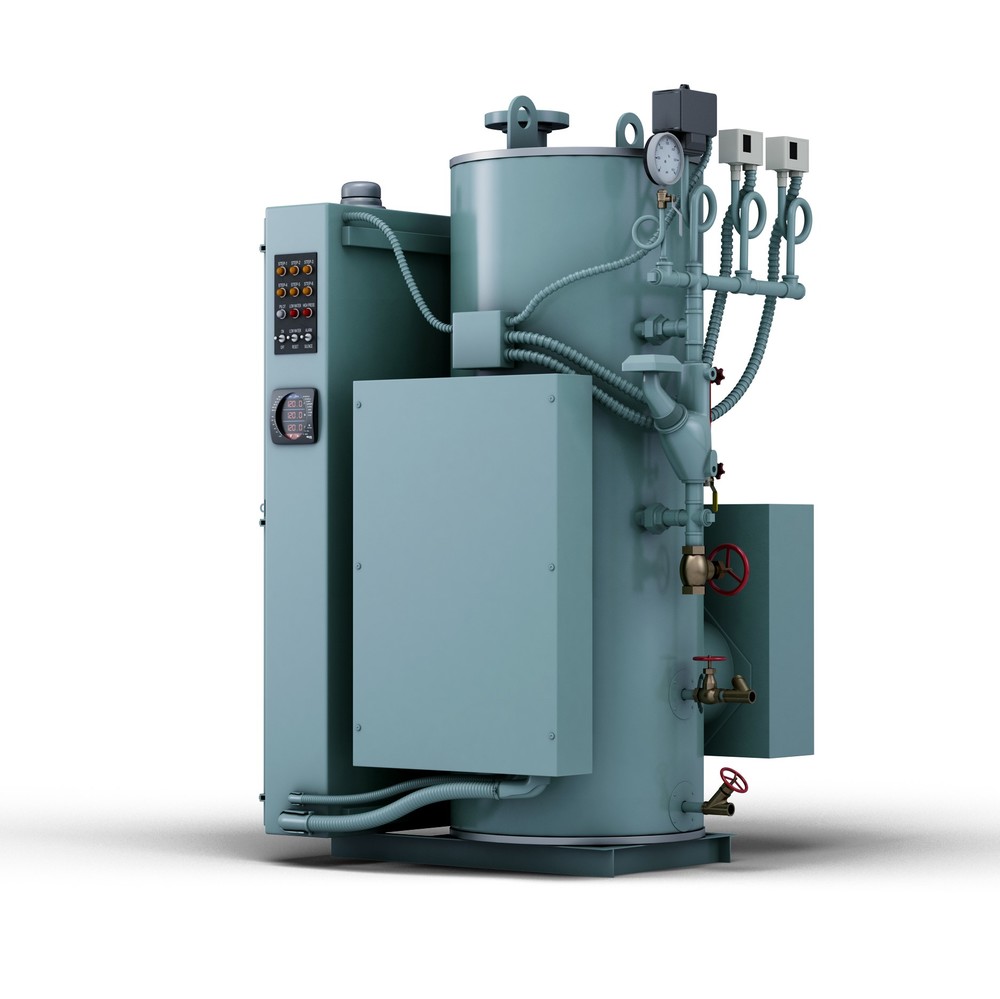

- Vertical Tubeless design for reliability and longevity

- Compact footprint with side mounted burner

- Large steam space

- Up to 50 HP

- Natural gas, propane

- 15 or 150 psig design

- Up to 84% efficient

- Up to 5:1 turndown

- Full modulation premix burner includes PID set-point control with built-in lead-lag functionality and touchscreen interface

- Skid package solutions available

- Thermal shock resistant

- Quiet operation – <70 dBA sound levels

- 5 year pressure vessel warranty

- cULus Listed

- ASME “H” or “S” stamped

- Control trim and gas train are ASME CSD-1 compliant

- External Economizer option

The CBT tubeless vertical boiler provides 99+% steam quality – low or high pressure – all delivered in a compact, easy to service vertical design to effectively and reliably meet your steam process requirements. The CBT tubeless boiler features thick pressure vessel plates that exceed ASME code requirements. The CBT has undergone exhaustive life cycle testing to ensure reliability and longevity. The side-mounted burner arrangement allows for a large steam space to deliver exceptional dry-quality steam, even at low pressure operation. The high-density, highly resilient insulating refractory minimizes thermal losses while helping maintain its compact footprint. Convenient hand-hole access and removable burner cover enhances the CBT’s serviceability. The integrated burner and controls keep the CBT operating at peak efficiency. Multiple burner and control options are available to suit your application needs. For the best operational efficiency and control, the full modulation, low-emission premix burner with 1:1 fuel-air ratio control and Falcon controller is available. The Falcon control includes built-in lead-lag functionality for systems with multiple CBT boilers.

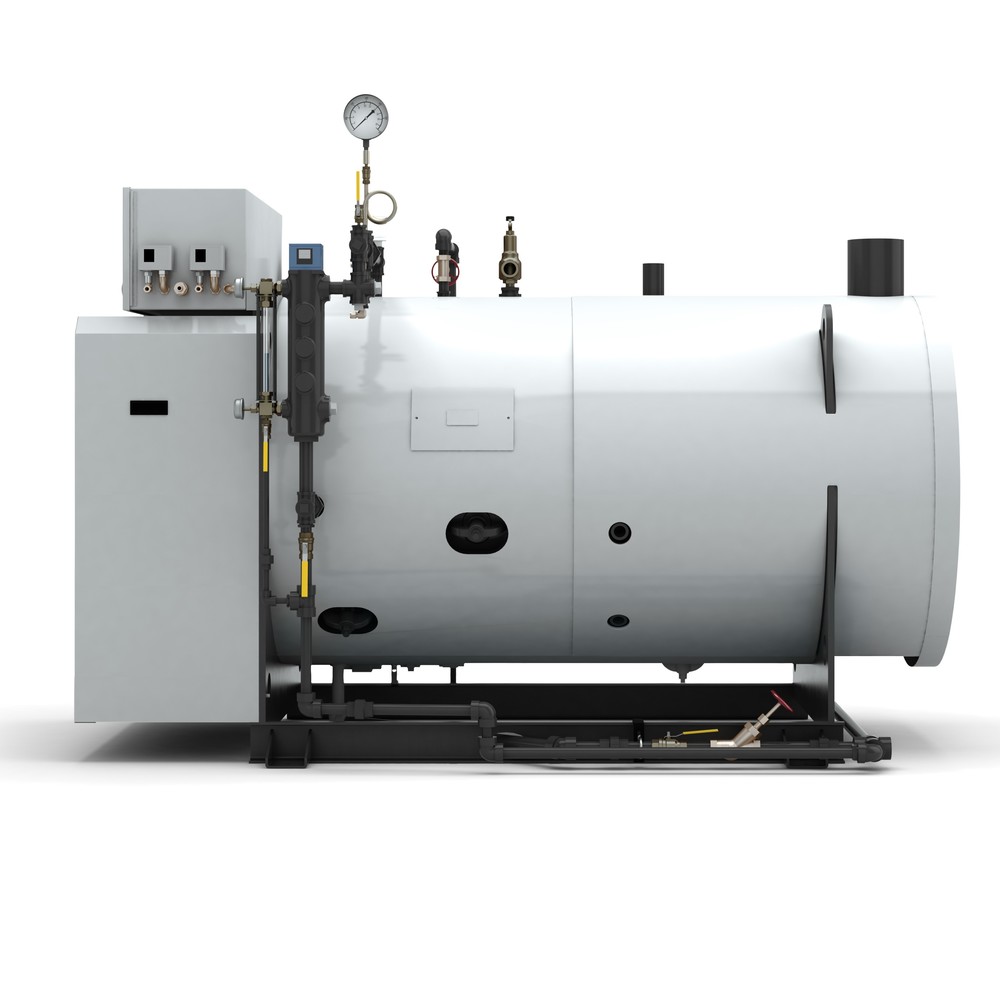

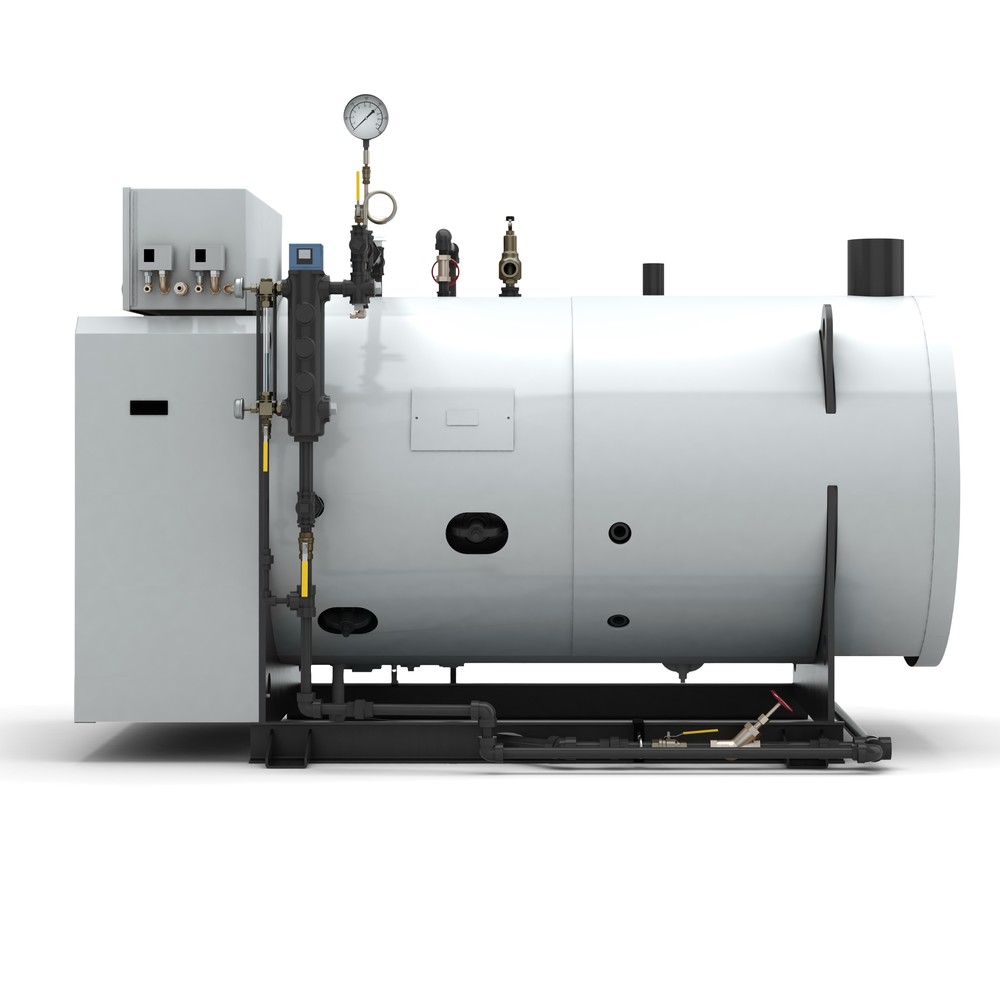

- Low and high pressure steam boiler

- 10-80 HP

- Natural gas, propane or combination

- 15 or 150 psig design pressure

- Up to 85% efficient

- Up to 10:1 fully modulating turndown

- Standard sub 20 ppm NOx, less than 10 ppm CO

- Alufer™ firetube technology for excellent heat transfer

- Maximize energy with full burner modulation and high turndown with variable-speed blower motor

- Sustainable design with lowest energy use and emissions

- Reliable operation with easy to use controls and burner technology

- Falcon boiler control with lead lag capability seamlessly integrates up to eight boilers

- Exclusive Integral CFH Economizer or external economizer options

- Skid package solutions available

- Thermal shock resistant

- Quiet operation — <70 dBA sound levels

- Dual fuel option

- cULus Listed

- ASME “H” or “S” stamped

- Control trim and gas train are ASME CSD-1 compliant

The ClearFire-H is a compact horizontal, gas-fired, steam boiler designed for all of your steam heating and process needs, available in ten sizes. The AluFer tubes with extended fireside heating surface provide maximum heat transfer for superior performance with a small installed footprint The premix burner automatically adjusts the air/gas mixture without the use of additional controls for optimum combustion performance, while the fully modulating burner delivers precise steam operating pressure meeting load requirements with minimum cycling. 85% efficiency is achievable for high-pressure steam with an optional flue gas economizer package. We guarantee 85% efficiency on low pressure steam. 99% or better dry quality steam assures the highest possible steam process performance and efficiency without the need for separators or additional process controls. The ClearFire-H comes standard with the Falcon touchscreen total boiler control to operate your boiler system. The optional Boiler Monitor solution allows for remote access to your boiler room from your computer or smart phone. Skid packages, including steam boiler, feed system, water treatment, and blowdown separator, are available for turnkey steam solutions.

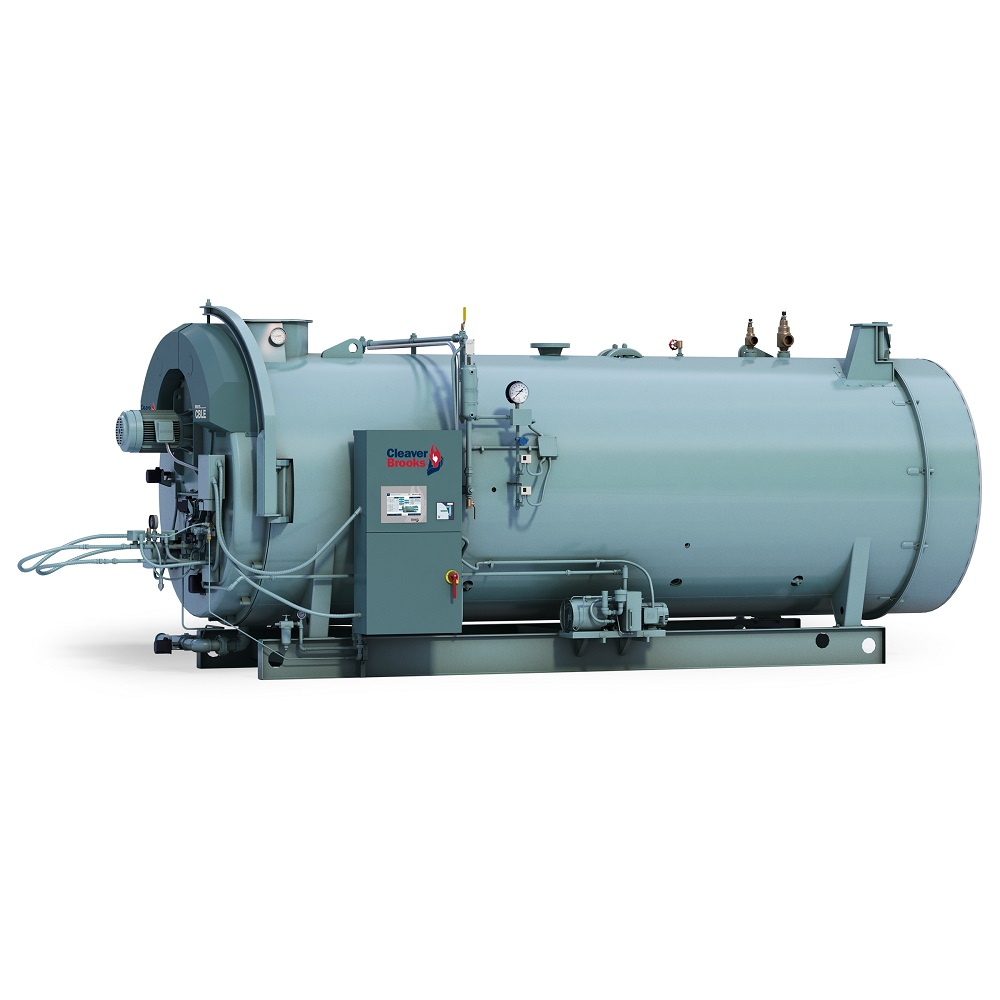

Steam up to 300 psig

Hot water up to 125 psig

50 to 800 HP

4 Pass

Natural gas/propane, #2 and #6 oil, combination

Alternate fuel capability

Waterback or Dryback design

60 ppm, 30 ppm, 9 ppm and 5 ppm NOx emission rates are available

Highest rated boiler efficiency of any scotch marine firetube boiler

Exclusive Cleaver-Brooks integral head burner with air-cooled front head

Hawk controls for maximum efficiency

Single source boiler, burner and control

Compact footprint

5 sq ft / BHP

Low NOx emissions available

Proven by 70 years of experience, the CBLE not only has a history of being reliable, but offers a compact footprint, maximum safety, easy maintenance and long life. Engineered by Cleaver-Brooks to provide a low lifecycle cost. The integral head burner of the CBLE coupled with its tube design enables the boiler to burn more types of renewable fuels than others in the market. The burner design also helps meet emissions reduction goals, down to <7 ppm NOx. The CBLE firetube boiler is a complete, single source package including pressure vessel, integral burner, and controls. Components are designed and manufactured for reliability and long life, maximum safety, ease of maintenance, and the lowest emissions, guaranteed. Upgrade or retrofit your system with Cleaver-Brooks controls, economizers, water treatment systems, and all the other system components to build a state-of-the-art boiler room of virtually any size and capacity.

Watertube Boilers

Optimal versatility in a highly efficient, compact unit.

- FLX

- FLX PM

- M5

- M5M

The Cleaver-Brooks Model S is an immersion-element steam electric boiler with a vertical, insulated vessel. This boiler is designed for the heavy-duty, continuous demand of commercial and industrial applications. Available in vessel sizes ranging from 12″ to 48″ diameter with an output spanning 12 kW to 2,250 kW. A typical Model S boiler system includes operating controls, elements, fuses, contactors, safety valve, and instrumentation.

- Electric vertical steam boiler

- 12 to 2250 KW – up to 7,875 lb/hr

- Up to 600V

- 15, 150, 200 & 250 psig

- No site emissions

- Compact design and smaller footprint

- No site emissions

- Quiet operation

- Nearly 100% efficiency at all operating points

- Ease of maintenance with reduced complexity/number of moving parts

- All units are fully packaged and ready for installation

The Cleaver-Brooks Model WB is an immersion-element hot water boiler with a vertical, insulated vessel. This boiler is designed for the heavy-duty, continuous demand of commercial and industrial applications. Vessel sizes range from 12″ to 42″ diameter with an output spanning 12 kW to 3,360 kW. A typical Model WB boiler system includes operating controls, elements, fuses, contactors, safety valve, and instrumentation.

- Electric hot water boiler

- 12 to 3360 kW, up to 11.5 million Btu/hr

- Up to 600V

- 160, 200 & 250 psig

- No site emissions

- Compact design and smaller footprint

- No site emissions

- Quiet operation with virtually no noise emissions

- Nearly 100% efficiency at all operating points

- Ease of maintenance with reduced complexity/number of moving parts

- All units are fully packaged and ready for installation