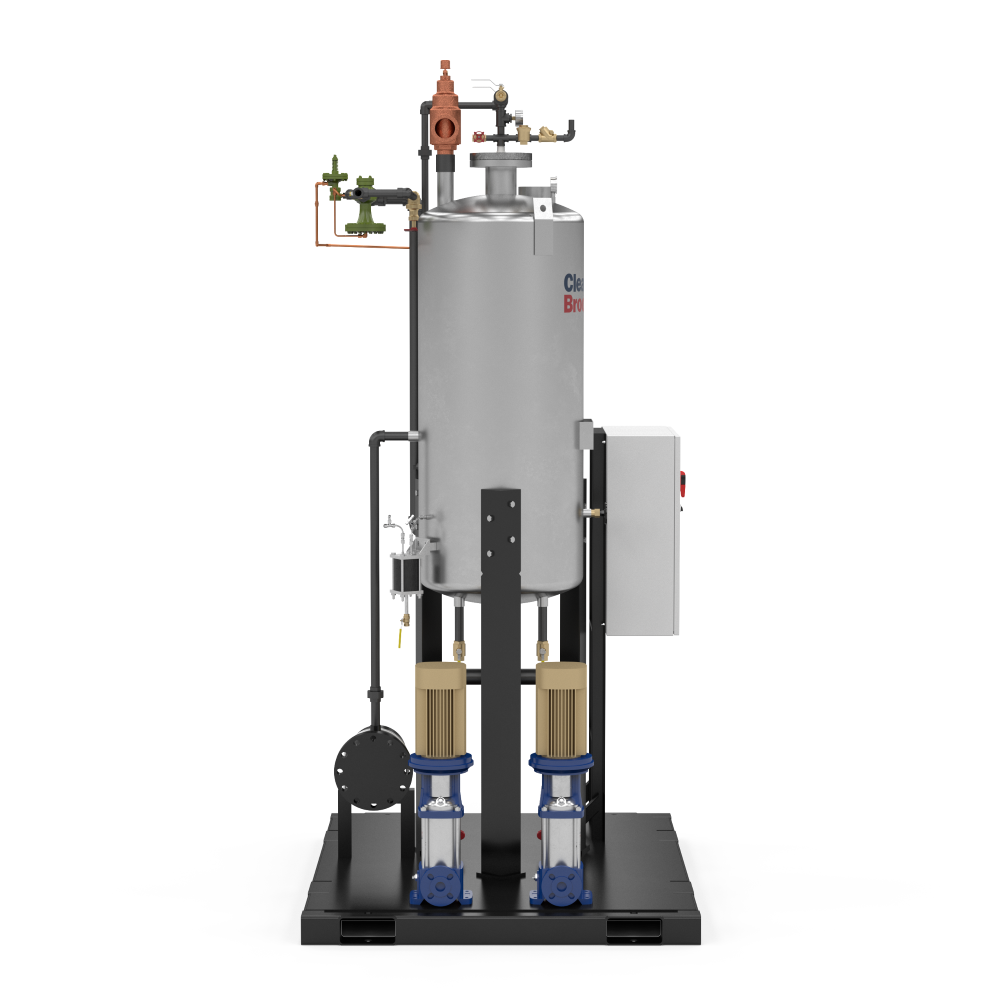

- Packed column deaerator

- 1,500 – 135,000 lbs/hr

- On/off and variable speed pumping

- Trouble free deaeration system

- Self-cleaning water spray valve

- Removable water spray inlet assembly

- Pressurized tank reduces flashing and minimal venting

- On/off or variable speed pumping

- Storage capacities from 10 to 30 minutes

The BoilerMate® deaerator is a pressurized packed column design where water is cascaded through a unique column design removing dissolved oxygen in boiler feed water and eliminating carbon dioxide. Flash steam from high temperature condensate return assists in deaeration improving the overall system efficiency. The package includes a packed column deaeration vessel and storage tank mounted on a stand with all operating controls, feed pumps assembled and piped (typically knocked down for shipment and field assembly). The BoilerMate deaerator is a trouble-free design where water is cascaded across large surface area packing material in the upper vessel. Steam is introduced to help drive off oxygen in the make-up water and condition it for delivery to the boiler. All of Cleaver-Brooks deaerators can be equipped with a wide range of options from basic manual controls up through full advanced digital operation depending on the needs of the system. Equip your Deaerator with the ADAC control system to provide the most advanced operation of your feed systems.

- 7,000-280,000 lbs/hr

- Low headroom design

- Combination spray type deaerator and surge tank

- On/off and variable speed pumping

- Combined deaerator and surge tanks

- Optional emergency bypass piping and controls

- Two-stage deaeration ensures maximum oxygen removal

- Internal stainless steel vent condenser

- Self-cleaning water spray valve

- Stainless steel deaeration assembly

- On/off or variable speed pumping

- Storage capacities from 10 to 30 minutes

The DuoTank product combines a surge tank with a SprayMaster deaerator into a single combined vessel, providing a complete engineered and packaged system. Reduces installation complexity and can save footprint over two tank systems. Highly configurable designs allow for integration of emergency bypass piping and controls to continue to feed the boiler when the deaerator section is offline for maintenance. The spray system in the Cleaver-Brooks SprayMaster deaerator is built of corrosion-resistant alloys for lifetime service. The deaerator employs those basic principles of gas removal proven most effective and economical to every steam boiler owner. With capacities ranging from 7,000 to 280,000 lbs/hr, the SprayMaster can be used in a wide range of steam plants. All of Cleaver-Brooks deaerators can be equipped with a wide range of options from basic manual controls up through full advanced digital operation depending on the needs of the system. Equip your Deaerator with the ADAC control system to provide the most advanced operation of your feed systems.

- Spray Type Deaerator

- 7,000-280,000 lbs/hr capacities

- On/off and variable speed pumping

- Low headroom design

- Two-stage deaeration ensures maximum oxygen removal

- Internal stainless steel vent condenser

- Self-cleaning water spray valve

- Stainless steel deaeration assembly

- Packaged units for cost effective installation

- On/off or variable speed pumping

- Storage capacities from 10 to 30 minutes

The Cleaver-Brooks designed SprayMaster deaerator is a proven design that assures high purity feedwater by removing oxygen and other dissolved gasses in boiler feed and maintaining consistent temperature feedwater to your steam boiler. The spray system is built of corrosion-resistant alloys for long life service. The deaerator employs those basic principles of gas removal proven most effective and economical to every steam boiler owner. With capacities ranging from 7,000 to 280,000 lbs/hr, the SprayMaster can be used in a wide range of steam plants. All of Cleaver-Brooks deaerators can be equipped with a wide range of options from basic manual controls up through full advanced digital operation depending on the needs of the system. Equip your deaerator with the ADAC control system to provide the most advanced operation of your feed systems.

- Vertical or horizontal tray column design

- Largest capacities available

- Most effective at oxygen removal

- Model TMV: 30,000 – 500,000 lb/hr

- Model TMH: 500,000 – 1,000,000 lb/hr

- On/off and variable speed pumping

- Less mechanical movement of deaerator components

- Two-stage deaeration in a common vessel

- Exceeds ASME recommendations for oxygen level

- Integral level control automatically introduces cold water makeup

- Supplement condensate only when necessary to meet boiler demand

- On/off or variable speed pumping

The TrayMaster deaerator is a pressurized, low-maintenance system designed to remove dissolved oxygen in boiler feedwater and eliminate carbon dioxide. This deaerator is offered in vertical and horizontal tray configurations. The design is recognized as the most versatile and efficient method of reducing dissolved oxygen content in boiler feedwater to levels less than .005 cc/liter (7 ppb) while also removing carbon dioxide. Built of corrosion-resistant alloys for lifetime service, the deaerator employs advanced principles of gas removal proved to be the most effective and economical to every boiler owner. Vessels are all factory tested, then assembled and broken down for shipment and ease of installation. All of Cleaver-Brooks deaerators can be equipped with a wide range of options from basic manual controls up through full advanced digital operation depending on the needs of the system. Equip your Deaerator with the ADAC control system to provide the most advanced operation of your feed systems.

- Packed column deaerator

- 2,000 – 7,000 lbs/hr

- On/off pumping

- Packaged, pressurized boiler feedwater system

- Produces deaerated water, protects boiler systems and piping from oxygen pitting

- User friendly, no PLC

- Durable, corrosion resistant design

The MiniMate® deaerator is a pressurized packed column design where water passes through a labyrinth of packing materials specially designed to agitate water and remove dissolved oxygen and carbon dioxide in boiler feed water. This packaged deaerator is a miniaturized version of the renowned BoilerMate design, specifically optimized for small-scale steam applications. Its compact, vertical tank arrangement fits seamlessly into tight spaces and steam skid packages, making it ideal for facilities with space constraints. Featuring a mechanical design that simplifies installation, startup, operation, and maintenance, this deaerator offers convenience and efficiency. The standard stainless-steel construction of both the tank and pumps ensures reliability, durability, and long service life.