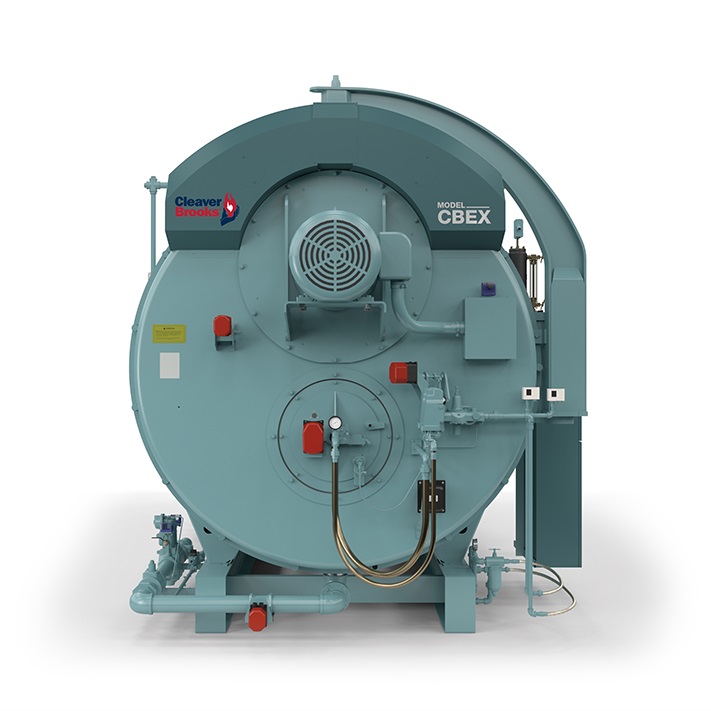

- Steam up to 300 psig

- Hot water up to 125 psig

- 100 to 2,500 HP

- 2 Pass

- Natural gas/propane, #2 light oil, combination

- Waterback or Dryback design

- Offers 30 ppm NOx with 3% O2 across the 10:1 turndown range

- Sub 5 ppm NOx without SCR available

- Meets 10 ppm CO requirement

- Highest operating efficiency of any scotch marine firetube boiler

- Exclusive Cleaver-Brooks integral head burner with air-cooled front head

- Hawk controls for maximum efficiency

- Single source boiler, burner and control

- Maximum excess air across the operating range

- Small footprint

The Cleaver-Brooks CBEX firetube boiler featuring EX technology is a completely integrated boiler, burner, and controls system. Every core component has been designed and built by Cleaver-Brooks to work together, resulting in the most efficient and lowest-emissions firetube system ever built. The CBEX achieves higher operating efficiency than competitors’ boilers, leading to lower fuel consumption over the life of the boiler. It can also burn renewable fuels and meets the lowest possible emissions of <5 ppm NOx, <10 ppm CO without SCR, helping achieve both emissions reduction and decarbonization goals. Using advanced engineering methods, design engineers designed the CBEX to optimize every component of the boiler, including the burner, the furnace, and the tubes, in order to provide optimally balanced heat release zones and minimizing thermal stresses in the boiler. Extended heat transfer tubes only found in EX systems uses Computational Fluid Dynamics (CFD) calculations to optimize the geometry of the tube and increase heat transfer by 85%. The result of the advanced heat transfer design is higher efficiency in a smaller footprint. Offered in a two-pass, waterback or dryback design, the CBEX boiler package is engineered for long life, highest part load (or operational) fuel-to-steam/water efficiency, maximum safety and lowest emissions. Its quiet operation, ease of maintenance and flexibility to add desired options further enhances the package. Integration of the core components is the key to the CBEX systems. The superior Hawk control allows the boiler to run at the absolute maximum efficiency. Reduce fuel use with the optional stack economizer by recovering waste heat from flue gasses and using it to preheat boiler feedwater. The LevelMaster low-water cutoff and pump control is the safest control available.

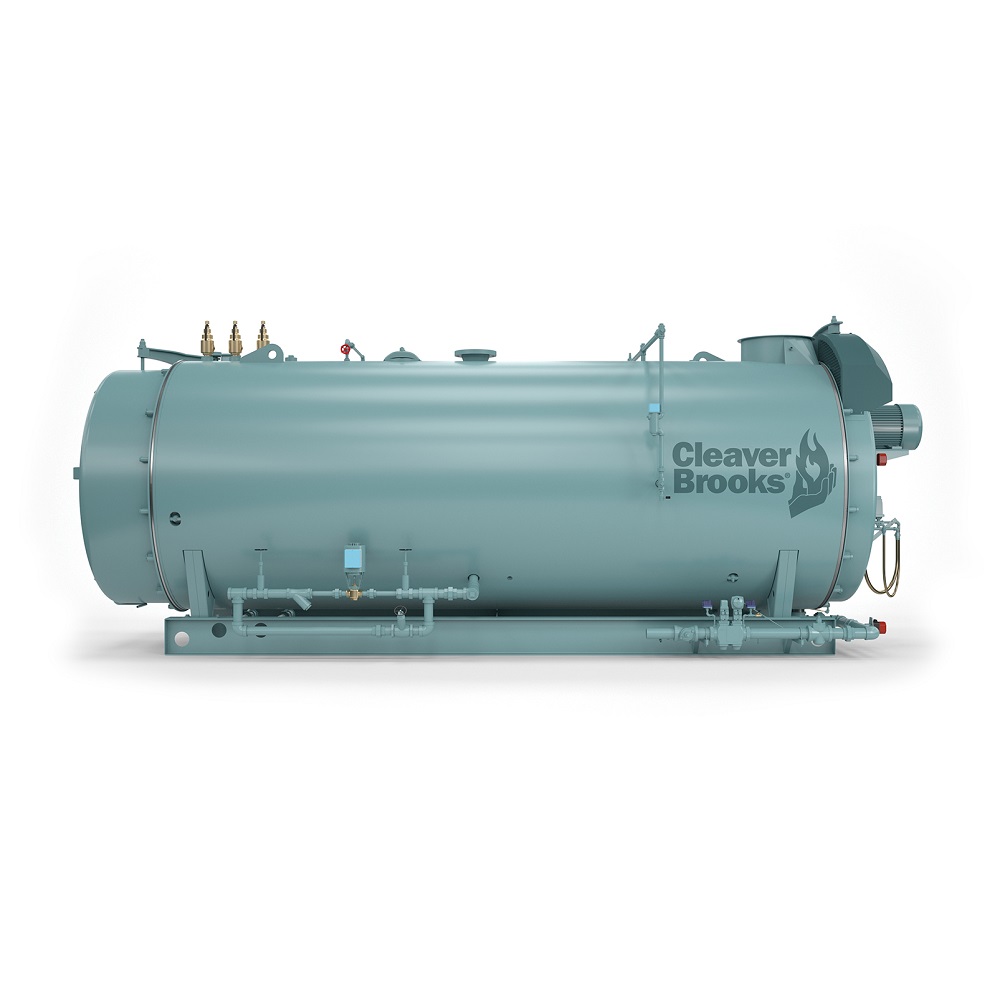

- Steam up to 300 psig

- Hot water up to 125 psig

- 50 to 1,600 HP

- 2, 3 and 4 Pass

- Natural gas/propane, #2 light oil, #6 oil or combination

- Dryback or Waterback design

- Available to < 30 ppm NOx emissions on 2 & 3 pass models

- Available to <9 ppm NOx emissions on 4 pass models

- Dryback or Waterback boiler design

- 5 sq ft / BHP or EX technology

- ProFire packaged jet burner

- Low emissions options available

- Hawk controls available

The Cleaver-Brooks CBJT firetube boiler has been designed to serve a wide range of applications. Built to utilize different Cleaver-Brooks exclusive technologies, from the robust pressure vessel, to the burner and controls, the CBJT is the ideal choice when an external jet burner is preferred. The CBJT features excellent fuel-to-steam/water efficiency and flexible burner options that can burn renewable fuels and help meet emissions reduction goals, lowering emissions to <30 ppm NOx and <50 ppm CO. The CBJT is a complete package, including pressure vessel, integral burner, and controls. Engineered by Cleaver-Brooks to be a fully compatible boiler and burner package featuring excellent fuel-to-steam/water efficiency, space savings, and low emissions. The versatile Cleaver-Brooks CBJT also has the flexibility to add desired options to further enhance the package. The CBJT is offered in a 2-, 3- or 4-pass design. It is ruggedly constructed for hot water or low and high pressure steam applications. For customers who prefer the jet burner design, the CBJT provides the highest value, with a focus on safety, ease of maintenance, lowest emissions and the flexibility to add desired options to further enhance the package. Upgrade or retrofit your system with Cleaver-Brooks controls, economizers, water treatment systems, and all the other system components to build a state-of-the-art boiler room of virtually any size and capacity.

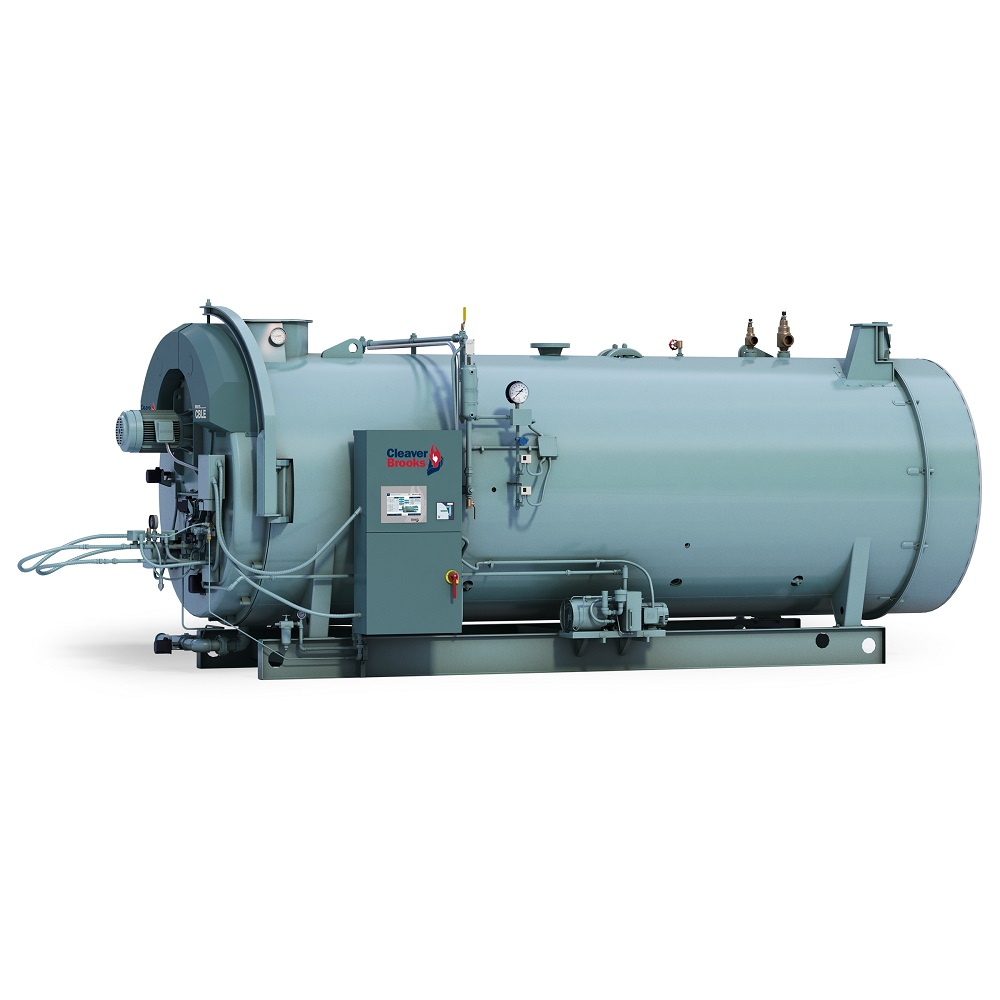

- Steam up to 300 psig

- Hot water up to 125 psig

- 50 to 800 HP

- 4 Pass

- Natural gas/propane, #2 and #6 oil, combination

- Waterback or Dryback design

- 60 ppm, 30 ppm, 9 ppm and 5 ppm NOx emission rates are available

- Highest rated boiler efficiency of any scotch marine firetube boiler

- Exclusive Cleaver-Brooks integral head burner with air-cooled front head

- Hawk controls for maximum efficiency

- Single source boiler, burner and control

- Compact footprint

- 5 sq ft / BHP

- Low NOx emissions available

Alternate fuel capability

Proven by 70 years of experience, the CBLE not only has a history of being reliable, but offers a compact footprint, maximum safety, easy maintenance and long life. Engineered by Cleaver-Brooks to provide a low lifecycle cost. The integral head burner of the CBLE coupled with its tube design enables the boiler to burn more types of renewable fuels than others in the market. The burner design also helps meet emissions reduction goals, down to <7 ppm NOx. The CBLE firetube boiler is a complete, single source package including pressure vessel, integral burner, and controls. Components are designed and manufactured for reliability and long life, maximum safety, ease of maintenance, and the lowest emissions, guaranteed. Upgrade or retrofit your system with Cleaver-Brooks controls, economizers, water treatment systems, and all the other system components to build a state-of-the-art boiler room of virtually any size and capacity.

Watertube Boilers

Optimal versatility in a highly efficient, compact unit.

- FLX

- FLX PM

- M5

- M5M

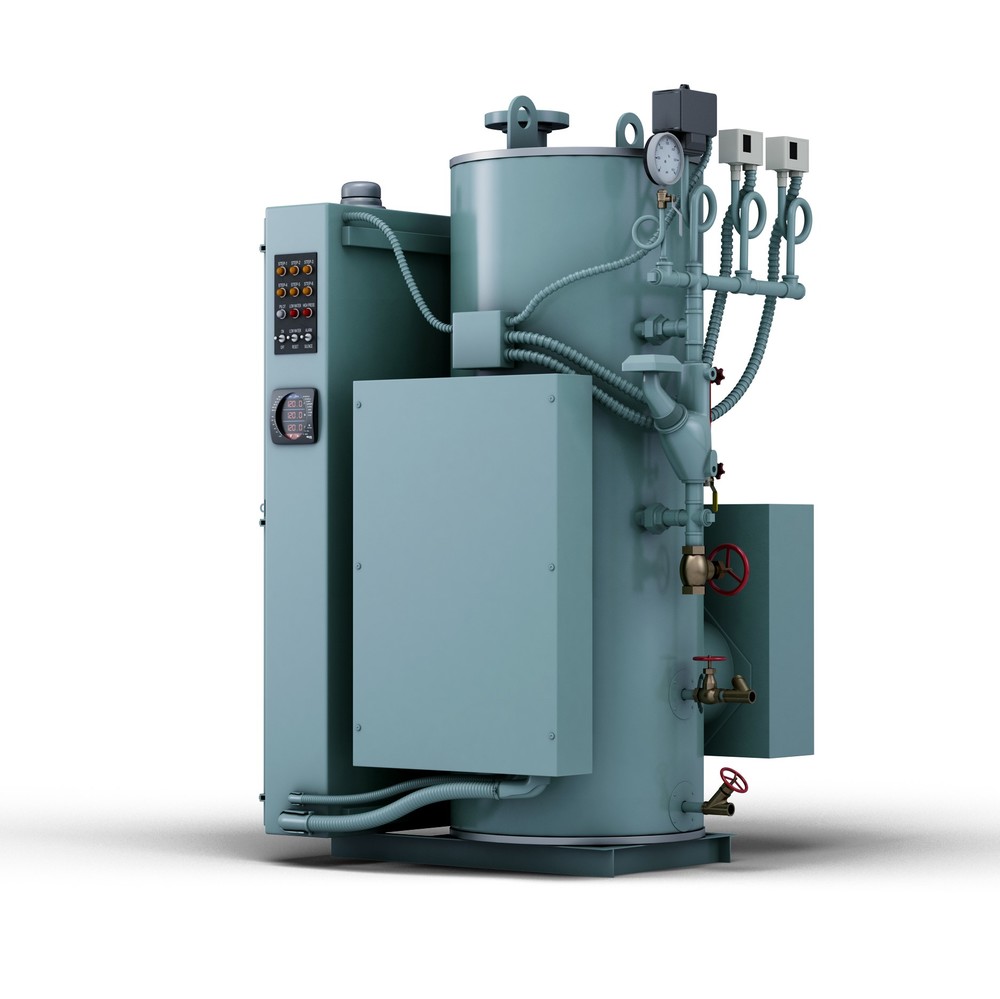

The Cleaver-Brooks Model S is an immersion-element steam electric boiler with a vertical, insulated vessel. This boiler is designed for the heavy-duty, continuous demand of commercial and industrial applications. Available in vessel sizes ranging from 12″ to 48″ diameter with an output spanning 12 kW to 2,250 kW. A typical Model S boiler system includes operating controls, elements, fuses, contactors, safety valve, and instrumentation.

- Electric vertical steam boiler

- 12 to 2250 KW – up to 7,875 lb/hr

- Up to 600V

- 15, 150, 200 & 250 psig

- No site emissions

- Compact design and smaller footprint

- No site emissions

- Quiet operation

- Nearly 100% efficiency at all operating points

- Ease of maintenance with reduced complexity/number of moving parts

- All units are fully packaged and ready for installation

The Cleaver-Brooks Model WB is an immersion-element hot water boiler with a vertical, insulated vessel. This boiler is designed for the heavy-duty, continuous demand of commercial and industrial applications. Vessel sizes range from 12″ to 42″ diameter with an output spanning 12 kW to 3,360 kW. A typical Model WB boiler system includes operating controls, elements, fuses, contactors, safety valve, and instrumentation.

- Electric hot water boiler

- 12 to 3360 kW, up to 11.5 million Btu/hr

- Up to 600V

- 160, 200 & 250 psig

- No site emissions

- Compact design and smaller footprint

- No site emissions

- Quiet operation with virtually no noise emissions

- Nearly 100% efficiency at all operating points

- Ease of maintenance with reduced complexity/number of moving parts

- All units are fully packaged and ready for installation